Architectural Material Prime Development, A Fundamental Solution offering corrosion and crack-resistant for Resilient Shelter, Stair, Bridge and Retaining Wall Foundation, Poles and Soil Nail. It is to transform bamboo structures in vulnerable communities and environments, shifting them from short-term and temporary construction investments to durable, long-lasting structures.

A simple Appropriate Technology and adaptable process emphasizes decentralized infrastructure and supports sustainable community development. An economically efficient alternatives to traditional horizontal soaking treatments and steel footers.

Outline:

1- Rohingya camp environment and population.

2- The Problem: the constant damage and constant replacement investment.

4- The proposed solutions.

5- Evidences of success.

6- Further potentials.

7- Bangladesh context, populations and the natural disaster (floods).

1- Rohingya camp environment and population.

Kutupalong (the mega camp) in Ukhia, Cox’s Bazar is the world’s largest refugees camp, 700,000 refugees fled from ethnic and religious persecution in neighbouring Myanmar. It is one of two government-run refugee camps in Cox’s Bazaar. The density of the population presents a significant challenge, with limited space, difficulties in accessing resources, and strain on existing infrastructure.

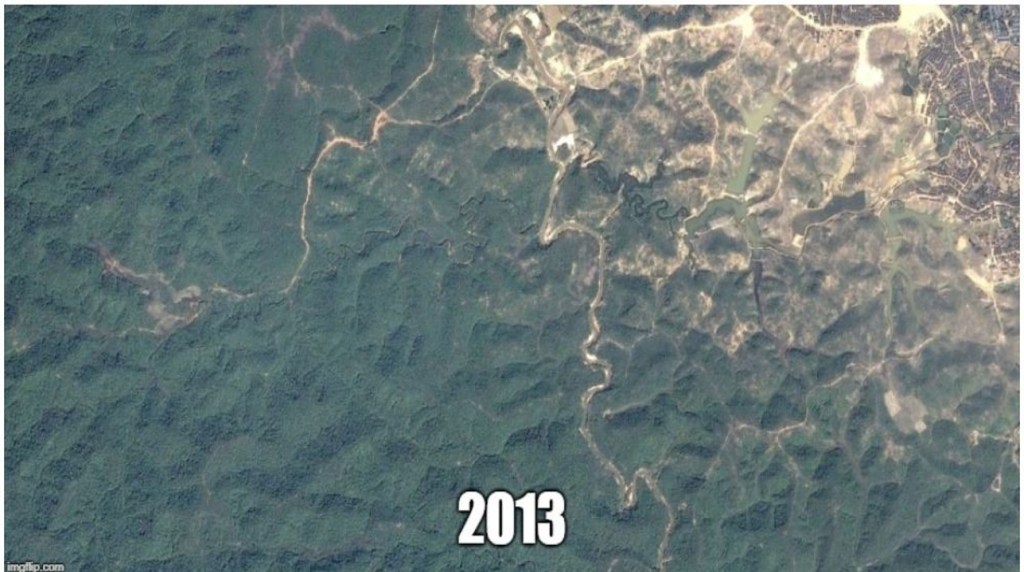

By late 2019, the development of the camps had been partially accomplished through the exploitation and destruction of 8,000 acres of forested area. Other environmental losses, estimated USD $290,400,000.

The damaged environment due to deforestation and the loss of plant roots and trees exacerbates these challenges and makes the camp more vulnerable to natural disasters.

The hilly landscape poses challenges for both access and stability, with landslides being a frequent concern. It’s crucial to steer clear of using cement and bricks in constructing stairs, retaining walls, shelter foundation slabs, and slope stabilization. These materials can heighten the risk of landslides, putting lives in jeopardy.

From the day one, Bamboo has been the mainstay of construction in the camps, shelters. Its strength, availability, affordability and ease of use make it an ideal choice for the community.

The Problem

Bamboo Corrosion and Cracking.

A- Corrosion: Due to termite attacks, the lifespan of untreated bamboo is 6 to 9 months when in direct contact with the soil. Outwardly, the damage may not be evident, except for a few 2mm diameter holes where termites bore into the bamboo to access the nutritious interior. Once they reach the core, termites will not vacate but instead continue to regenerate and spread inside the pole.

B- Cracking: when the bamboo directly exposed to the natural factors, a longitudinal cracking of bamboo caused by the difference in relative humidity between the rain and dry seasons.

As it is obvious to the community that bamboo is not lasting, a significant portion of the camp has been constructed with an emergency mindset, leading to the prevalence of temporary structures. Bamboo structures like shelters, retaining walls and bridges are inherently fragile and pose a considerable risk.

The average lifespan of a bamboo structure is 18 months in the best scenarios. Therefore, constant work is required to maintain and replace damaged parts.

The Horizontal Soaking Bamboo Treatment Method

The borax and boric acid bath treatment process, while common, incurs significant costs and operational challenges. Typically, this treatment can increase the cost of bamboo by 120% to 180%, demanding intensive labor and logistical coordination. Centralized treatment facilities also necessitate bamboo to be transported twice, adding to the cost.

Moreover, despite this costly treatment, bamboo shelters still require additional measures for durability. Specifically, steel footers are used to elevate bamboo poles off the ground to protect them from termite damage. For just one shelter, the need for 13 such footers can escalate the construction costs by an additional $150 to $180.

There are also environmental concerns with the widespread use of borax and boric acid. When used extensively, these chemicals have the potential to leach into the ground, posing a risk of groundwater and soil contamination within the camp environment. Over time, this can lead to broader ecological impacts, undermining the sustainability of the treatment method.

Conclusion.

Ultimately, the CCCM sector, after passing the emergency state of the response, it is the time to consider the safety of the beneficiaries and the environment, while also ensuring the cost-effectiveness and efficiency of their operations. Revaluating and potentially restructuring the bamboo treatment process can help achieve these objectives and ensure sustainable and effective shelter solutions in camps.

The proposed olution

PET Plastic Water Bottles laminated Bamboo.

It is simply covering the bamboo with non-degradable and durable materials to physically prevent the termite from reaching the bamboo, Ultimately, the process is designed to be localized/community-based, locally fabricated, simple to use, low-cost and easily replicable.

Plastic laminating the bamboo will increase the lifespan to minimum 8 to 10 years. The proposed sustainable method is utilizing non-degradable materials, such as waste (PET bottles in this case).

The process.

An appropriate design-based craft, The process is simple, scalable, affordable, and portable, incorporates local skills and resources.

Resources.

In the coastal region in Cox’s Bazaar, In an average day, Hotels, guest houses, and motels, are producing approximately 30,000 to 50,000 of PET plastic water and beverages bottles of different sizes.

A hill of 60 shelters will require 150,000 k to 200,000 bottles to protect all the structures including, stairs, drains, retaining walls.

Evidences of success.

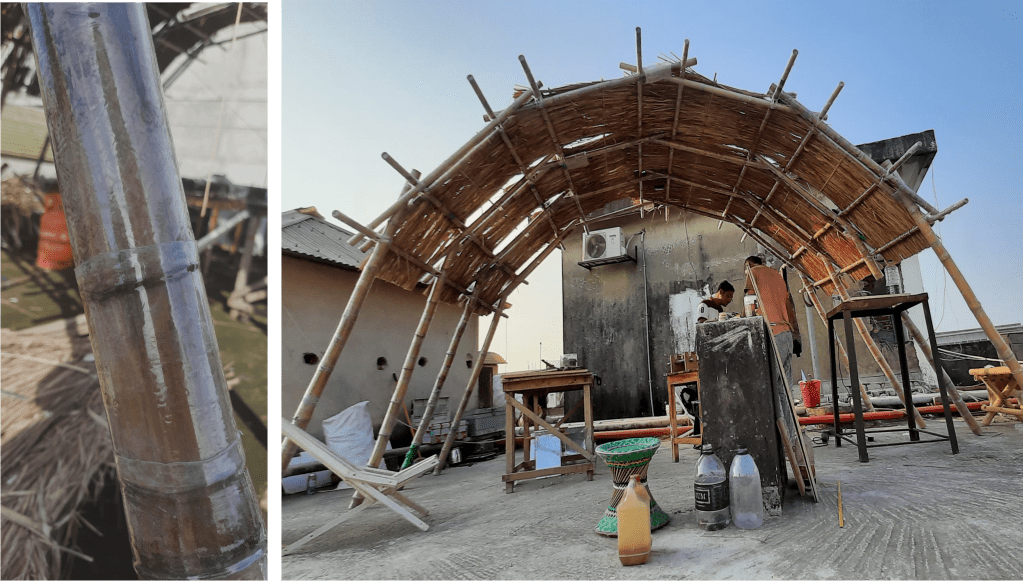

1- A self-supporting arched structure serving as a shade, situated in Cox’s Bazar, depicted immediately after construction in January 2021. This structure, fully exposed to the elements, including direct sunlight and rain, stands as a testament to the initial application and potential resilience of the laminating bamboo technology.

The following pictures and videos showcase the same structure, now photographed 22 months later in December 2022. Despite continuous exposure to harsh weather conditions, no damages were observed—no cracks, corrosion, or any signs of termite attack. The structure exemplifies the enduring strength and effectiveness of laminating bamboo technology. This comparison highlights the significant enhancement in bamboo’s durability and reliability as a construction material.

The accompanying video depicts bamboo that has not undergone the encapsulation process, subjected to the same environmental conditions over a 22-month period as its treated counterpart. These visuals vividly illustrate the contrast in durability between the encapsulated and non-encapsulated bamboo. The untreated samples clearly show cracking, highlighting the traditional bamboo’s vulnerability when exposed to direct sunlight.

2- Flower Beds constructed in January 2022, at MahduCharah Hub, using plastic-encapsulated Mulli bamboo, each 60 mm in diameter. The laminated bamboo is in direct contact with the humid soil, plants, living organisms, and bacteria, posing a real test to its durability and resistance to biodegradation.

The subsequent pictures, captured 15 months later, revisit the same flower beds to illustrate the encapsulated bamboo’s durability and condition over time. No termite attacks or cracking were observed. These comparative images aim to highlight the enduring quality and structural integrity of the encapsulated bamboo, demonstrating its resilience despite the elapsed time and exposure to environmental elements.

These visual evidences effectively showcase the laminating bamboo technology’s capacity to maintain the physical and functional integrity of the installations. The stark comparison presented underscores the significant protective benefits and enhanced resilience provided by the technology, emphasizing its effectiveness and value in prolonging the lifespan and utility of bamboo-based structures.

Potentials.

Bangladesh is a densely populated country with a high risk of natural disasters, including floods, cyclones, and landslides. These disasters cause widespread constant damage to infrastructure, homes, water and sanitation facilities, croplands, and fisheries.

Laminating bamboo technology provides a versatile, cost-effective solution, especially beneficial for resource-limited or vulnerable communities. Its minimal equipment requirements facilitate widespread adoption, making significant strides in sustainability by repurposing recycled water bottles. This innovation not only enhances bamboo’s durability but also expands its use across various scales of infrastructure, from small shelters to larger municipal projects like bridges and embankments.

Adaptability to Different Contexts: The technology’s simplicity ensures it can be tailored to diverse environments and project requirements, enabling its application in everything from microbudget initiatives to significant infrastructural developments.

Economic Advantages: The transition from wood poles to encapsulated bamboo can significantly lower construction costs, making infrastructure like shelters, coops, and other structures more feasible and economically sustainable. This cost-effectiveness translates into a viable, long-term investment, demonstrating the technology’s value in reducing financial burdens associated with construction and maintenance.

The encapsulated bamboo is showing up to 20 % increase in the stress strength, with construction designing, heavy bridges could be constructed and guaranteed.

Social and environmental Impact: Utilizing encapsulated bamboo contributes to forest preservation by offering an alternative to timber, thus reducing deforestation and its associated impacts. Moreover, its application in constructing and retaining road embankments showcases its effectiveness and reliability in essential infrastructure development, further underscoring its potential for broad environmental benefits.

Support and Collaboration: Encouraging partnerships with NGOs, community leaders, and policymakers can facilitate the technology’s integration into mainstream construction practices, enhancing its impact and reach.

Scalability and Future Research: Ongoing innovation and research can further refine the technology, broadening its applications and efficiency. As it evolves, its potential for larger and more complex constructions could grow, highlighting its scalability.

Global Relevance: Beyond its immediate benefits, the technology holds promise for global adoption, offering a sustainable building solution that mitigates carbon footprint and supports eco-friendly development practices worldwide.

By emphasizing these aspects, the narrative underscores the technology’s broad applicability, economic benefits, and positive environmental and social impacts, positioning it as a key player in sustainable global infrastructure development.

In conclusion, while bamboo is globally recognized as a sustainable material with broad applications in various industries, its potential in infrastructure, particularly through the innovative laminating bamboo technology, is yet to be fully realized. This method has demonstrated significant promise within the Rohingya camps, offering a durable, cost-effective, and environmentally friendly solution for construction and infrastructure needs.

Despite its proven benefits, this technology has not reached its full scope of influence within the camps, as many NGOs and stakeholders remain unaware of its potential. The urgency to disseminate this knowledge and encourage adoption at a larger scale cannot be overstated. The success of laminating bamboo in these settings can serve as a beacon for similar humanitarian and development contexts, notionally and worldwide.

Therefore, this post serves as a call to action for all entities operating within and around the Rohingya camps and beyond. It is an invitation to explore, adopt, and advocate for laminating bamboo technology to transform the landscape of sustainable construction and make a tangible difference in the lives of those residing in such vulnerable settings.

By embracing this technology, NGOs and other stakeholders can lead a paradigm shift toward more sustainable, resilient, and cost-effective construction practices, setting a precedent that could inspire and influence global standards in humanitarian infrastructure development.

Leave a comment